- This topic is empty.

-

AuthorPosts

-

2025-12-17 at 6:16 pm #5851

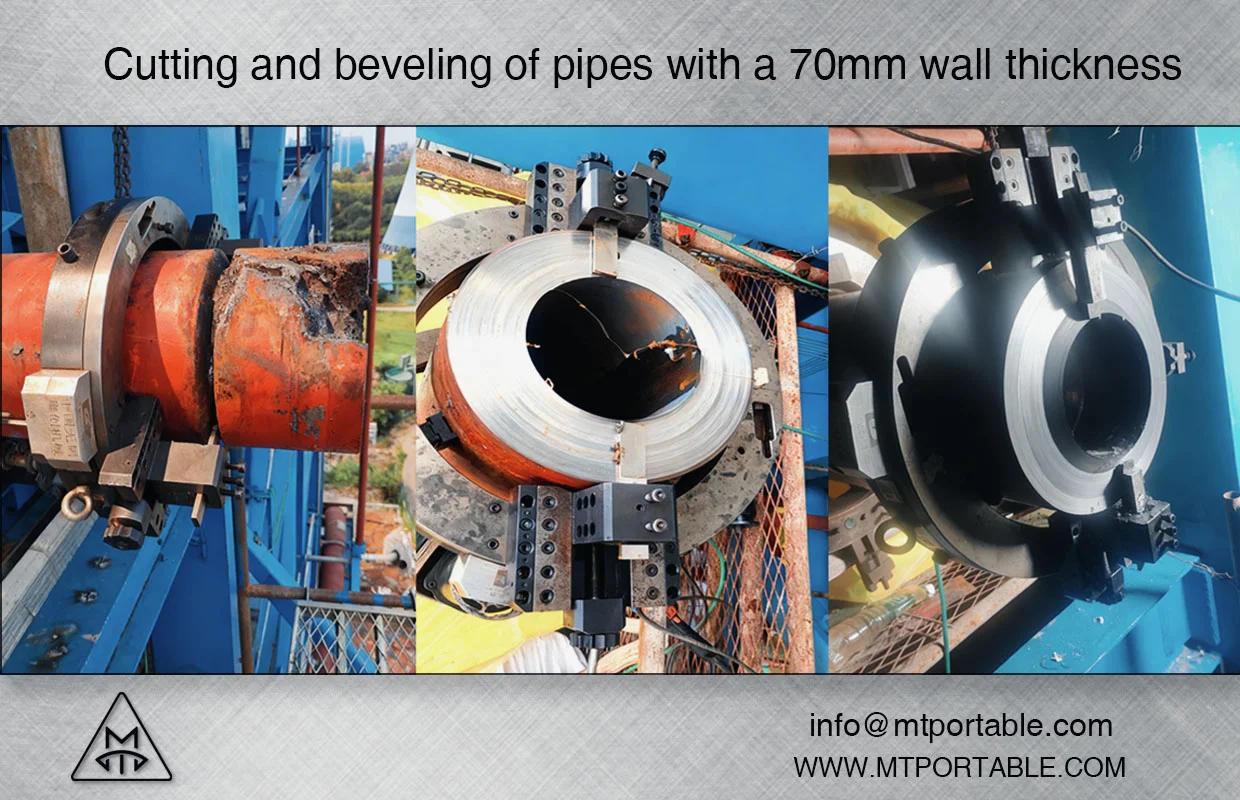

At a key project site operated by China Energy Engineering Group, on-site cutting and beveling was required for a 70mm thick-wall pipe to meet the stringent requirements of an industrial pipeline installation. To accomplish this technically demanding task, the customer selected the MT Portable Machine pipe cutting and beveling machine, which is specifically designed for pipe machining applications requiring high weld-edge accuracy.

Thick-wall pipes, especially those with a wall thickness of 70mm, are widely used in power plants, petrochemical facilities, LNG receiving terminals, and refinery systems, where pipelines must withstand high pressure, elevated temperatures, and corrosive media. In such applications, the accuracy of pipe cutting and beveling directly affects weld quality, structural integrity, and long-term operational safety. Compared with standard pipes, thick-wall pipes present significantly greater machining difficulty due to higher material hardness, increased cutting resistance, and more stringent dimensional tolerances.

During the initial machining attempt, the operation was unsuccessful due to improper feed rate and cutting parameter settings. Recognizing the urgency of the situation, the MT Portable Machine technical support team responded immediately and dispatched experienced field engineers to the site. Upon arrival, the MT team carried out a comprehensive evaluation of the pipe material grade, wall thickness, outer diameter, and on-site installation conditions, and optimized the machining plan accordingly.

By selecting the most suitable machine model and tool holder assembly, and installing cutting tools designed for thick-wall steel pipes, MT technicians successfully restored the equipment to optimal operating condition. The MT pipe cutting and beveling machine ultimately delivered a smooth cut, high squareness, and a uniform bevel that fully met welding standards, in full compliance with project technical specifications.

The operation was completed with high efficiency and excellent surface finish quality. The produced bevel angle satisfied subsequent welding requirements, significantly reducing the risk of pipe misalignment and minimizing the need for secondary machining. This successful result once again demonstrated the reliability, stability, and superior adaptability of MT Portable Machine equipment in complex on-site conditions.

In thick-wall pipe machining, ensuring tool stability and maintaining consistent cutting performance throughout the entire wall thickness is a major challenge. Without a properly engineered, rigid machine structure and professional operational expertise, issues such as excessive vibration, accelerated tool wear, and uneven surface finish can easily occur. The MT team’s rapid and professional intervention clearly highlighted the importance of selecting the right equipment configuration and relying on an experienced technical team for complex field machining tasks.

The success of this project further strengthened MT’s position as a trusted provider of portable on-site machining solutions for heavy industries. With extensive experience in pipe cutting, beveling, flange facing, and various on-site machining applications, MT Portable Machine continues to support customers worldwide by delivering professional equipment and technical services that combine high precision, strong portability, and outstanding durability.

If you encounter any on-site pipe machining challenges or require technical assistance, please contact the MT Portable Machine technical team to obtain the latest product specifications and professional solutions for your field machining requirements at info@mtportable.com

http://www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd -

AuthorPosts

- You must be logged in to reply to this topic.