- This topic is empty.

-

AuthorPosts

-

2025-12-17 at 6:16 pm #5852

You now see a new time in orthodontics. The robotic invisible braces production system changes how clear aligners are made in 2025. Companies like ConverSight lead this change. They use AI, robotics, and digital workflows together.

-

AI helps doctors find problems better and predict treatments.

-

Digital workflows like CAD/CAM make producing braces faster and more precise.

New robotics, such as multi-axis machining, enhance the functionality of invisible braces. They also ensure greater consistency for manufacturers and patients.

Key Takeaways

-

Robotic automation makes invisible braces faster to make. You can get your aligners in only a few hours.

-

AI technology helps plan your treatment better. It finds problems early. This makes your orthodontic care more personal and works better.

-

Digital workflows and 3D printing help each aligner fit well. This means you feel less pain and need fewer changes.

-

Modular equipment design lets workers change machines quickly. This helps them make different braces fast, without waiting.

-

More people around the world want clear aligners. New technology makes them better and improves service.

Robotic Invisible Braces Production System

The robotic invisible braces production system is very important in digital orthodontics in 2025. This system uses automation, robotics, and AI to make everything work smoothly. Companies like ConverSight use new automation tools. DHR Engineering makes lots of braces fast. These new machines change how you get invisible braces. Now, braces are more exact and easier to get.

End-to-End Automation Workflow

You can see how an invisible brace is made with this system. Every step uses machines to make things faster and more correct. Here is what happens:

-

Intraoral Scanning & Virtual Setup: First, your teeth are scanned in high detail. Then, software plans your treatment and shows a digital model.

-

LuxDesign™ CAD Shell Creation: The system uses CAD tools to set the aligner’s thickness and attachments. This makes sure the right force is used for your teeth.

-

LuxFlow™ Print Preparation Software: The software gets the digital model ready for 3D printing. It checks every detail before printing.

-

Direct Printing with iLux Pro Dental Printer: The printer makes the aligners quickly and very accurately. You get a good fit each time.

ConverSight’s system uses AI and robots at every step. Machines shape the aligners. Other machines cut them to the right size. Lasers put marks on them for ID. These steps need little help from people, so the quality stays the same.

DHR Engineering’s machines can make thousands of aligners every day. This shows how fast and good automation can be.

Tip: When machines do all the steps, there are fewer mistakes. You get your braces faster and they fit your plan well.

Modular Equipment Design

Modular equipment design helps in the robotic invisible braces production system. This means machines can be changed fast for different braces. It is easy to handle simple or hard cases without stopping.

-

Modular machines can be changed for new products.

-

They help with hard cases easily.

-

You get good results even if more braces are made.

ConverSight’s modular design lets you add or upgrade machines as needed. This keeps the system working well and ready for the future. The machines stay reliable, no matter how many braces are made.

Note: Modular machines work for small clinics and big labs. You always get good care.

The robotic invisible braces production system uses automation, modular design, and digital tools. You get better braces, faster service, and more choices for your teeth.

Automation Trends in 2025

Invisible braces production in 2025 is changing a lot. New technology is used at every step. These changes help you get better results and faster service. You also have more choices for your braces. Digital imaging and 3d scanning make things more exact. Data analytics helps guide each part of the process. Let’s look at the biggest trends in invisible braces production.

AI Integration in Manufacturing

AI is now very important in making invisible braces. This technology gives new ideas at every step. Digital imaging and 3d scanning take clear pictures of your teeth. AI looks at these pictures and finds small problems. You get a treatment plan made just for you.

Here are some new trends you see with AI in making braces:

-

AI imaging helps you plan your treatment better. You see your teeth in great detail.

-

Digital scans take the place of old impressions. You get more exact results.

-

AI can guess how your teeth will move. You know what will happen next.

-

Treatment time is about 25% shorter. You finish sooner.

-

AI finds problems early, like crowding or overbite. You get help right away.

-

AI picks the best order for your aligners. You get the most out of each one.

-

Data analytics lets orthodontists watch your progress. You see how your treatment is going.

-

AI makes plans that change as your teeth move. You get a plan that fits you.

-

More people are happy because AI makes things easier.

Tip: Using AI and data analytics gives you better results. Your braces fit well, and you finish faster.

3D Printing and Digital Workflows

3d printing and digital workflows are big trends now. These tools make the process quicker and more exact. You get your aligners fast, and they fit well.

Here is how the digital workflow helps you:

Step

Description

1

Intraoral scanning takes very clear digital pictures of your teeth, with accuracy between 20-50 microns.

2

Treatment software uses AI to design your aligners.

3

The design goes right to LuxFlow for print prep. No file changes are needed.

4

The aligner is printed with the iLux Pro Dental printer. Cleaning and curing come next.

5

The whole process from scan to delivery takes only 2-3 hours. You get your braces much faster.

6

You see a 19% drop in cost for each aligner compared to old ways.

You see more new trends in digital workflows:

-

Cloud-based patient management lets you check your progress anywhere.

-

Smart dental wearables track how long you wear your aligners. You get reminders and tips.

-

Digital tools help orthodontists plan your treatment better.

-

Eco-friendly materials and steps help the planet. You get care and help the earth.

-

Patient-focused care puts your needs first. You get more choices and better service.

Note: 3d scanning and digital workflows give you more insights and faster results. Technology makes your treatment easier and better.

You see these automation trends everywhere in invisible braces production. You get new technology, better ideas, and faster service. These trends make orthodontic care easier and work better for you.

Impact on Efficiency and Quality

Precision and Consistency

You want your invisible braces to fit well. Robotic automation helps make this happen. Machines use sensors and software to shape each aligner. Robots do not get tired or make mistakes like people.

-

Robots help stop human errors, so your aligners fit your plan.

-

Every set of braces is made the same way.

-

AI and robots work together for a perfect fit.

-

The system checks each step and makes changes if needed.

Your treatment feels easier and more steady. Precision tools help your braces move your teeth as planned. You feel sure about your orthodontic care.

Tip: When your treatment is steady, you reach your goal faster and with fewer problems.

Reduced Manual Intervention

You spend less time at the dentist because of automation. AI software does most of the planning and design. You do not need messy molds or long visits. Digital scans and machines do the work now.

-

AI and automation help doctors plan and diagnose better.

-

The system shows your results and makes each aligner just for you.

-

Automated 3D pictures take the place of old molds.

-

Robots make braces faster and use less material.

You get more done at each step. The process is quicker, and you get your aligners sooner. Less manual work means fewer delays and a better experience.

Note: If you pick a clinic with robotic automation, you get faster service and better results.

Market Growth and Adoption

Global Demand for Clear Aligners

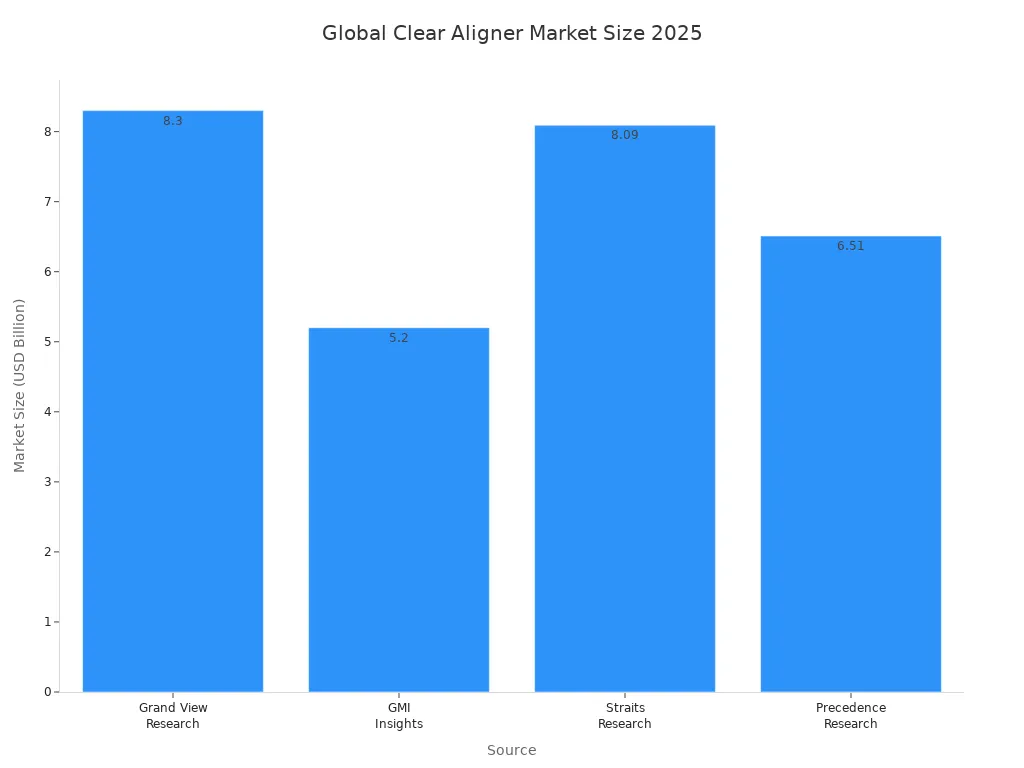

The global prealigners market is changing quickly in 2025. More people want invisible braces, so the market keeps getting bigger. The size of the global prealigners market is growing a lot. North America, Europe, and Asia are seeing more people use prealigners. In North America, many people already use prealigners. Europe has many dentists, so more people get prealigners there. Asia Pacific and Latin America have the fastest growth. People in these places have more money and want nicer smiles. The global prealigners market is meeting what people want for clear aligners.

Here is a table that shows the size of the global prealigners market in 2025:

Source

Market Size in 2025

CAGR (2025-2030)

Grand View Research

31.3%

GMI Insights

USD 5.2 billion

N/A

Straits Research

USD 8.09 billion

30.18%

Precedence Research

USD 6.51 billion

N/A

The global prealigners market is growing very fast. It could reach $21.2 billion by 2030. The market is growing at a rate of 16.8% from 2024 to 2031. Both teens and adults want prealigners. More people in new countries can get dental care, so the market grows. People have more money and more dental problems, so the market gets bigger.

Competitive Advantages

Manufacturers use robotic automation to do better in the global prealigners market. Robotic automation gives you better quality and faster service. Advanced systems help make prealigners quickly. Robots help stop mistakes and make sure quality is good. AI and machine learning help check quality and make production better right away. The global prealigners market gets better because of these changes. You get prealigners that fit well and come faster. More clinics and labs use robotic automation, so the market grows. The market for prealigners is now more reliable and works better. The global prealigners market keeps changing to help you.

Tip: If you pick prealigners made with robotic automation, you get better results and faster delivery. The global prealigners market works hard to give you great care.

Patient and Professional Benefits

Customization and Fit

You want braces that fit your teeth perfectly. In digital dentistry, you get this level of care. AI and robotics work together to make sure your invisible braces match your mouth. You see the benefits of digital dentistry in every step. Here is how you get a better fit:

-

AI looks at 3D scans of your teeth and face. You get a treatment plan made just for you.

-

Digital dentistry lets the system shape each aligner to match your teeth. You feel less discomfort and need fewer changes.

-

The technology checks for problems with bracket placement. You get adjustments before you even wear your braces.

You notice that digital dentistry makes orthodontics more personal. You do not have to worry about braces that do not fit. The process uses advanced manufacturing and digital dentistry tools to give you the best results.

Tip: When you use digital dentistry, you get braces that fit better and feel more comfortable.

Faster Delivery

You do not want to wait long for your new smile. Digital dentistry speeds up the process for you. You see how digital dentistry and robotics make everything faster in orthodontics. Here is what happens:

-

AI tools help the team work faster and do less manual work. You finish your treatment sooner.

-

Digital dentistry software checks your scans and makes a plan quickly. You do not wait for weeks.

-

The system can show how your teeth will move. You get results faster.

-

Digital dentistry checks how well your aligners work. You get changes right away if needed.

-

Remote monitoring lets your doctor see your progress. You do not need to visit the clinic as often.

You get your invisible braces in less time. Digital dentistry makes orthodontics easier and faster for you. You spend less time waiting and more time smiling.

Note: Digital dentistry gives you a faster, smoother experience from start to finish.

Challenges in Automation

System Integration

Bringing automation to invisible braces production is not easy. One big problem is getting all the machines and software to work together. Sometimes, different tools do not connect well. You want everything to work smoothly, but this is hard. Some machines and programs do not use the same codes. You need rules so every part fits together. Adding new machines to old systems can mess up your work. You want to keep your service good while you make changes.

Here is a table that shows the main technical barriers in system integration:

Technical Barrier

Description

Interoperability Issues

Making sure different software and digital tools in orthodontics can talk to each other easily.

Need for Standardized Technology

Creating rules for digital tools like 3D imaging and planning software.

Integration Challenges with Existing Systems

Adding new technology to old ways of workin

http://www.conversighttech.com

ConverSight Technology Limited -

-

AuthorPosts

- You must be logged in to reply to this topic.